How to Apply

Interested in participating in this research project? Contact the professor or graduate student listed below.

Professor

Dr. Ali Dhinojwala (Polymer Science) | ali4@uakron.edu

Graduate Students

Anvay Patil | aap82@zips.uakron.edu

Mario Echeverri | mecheverri@zips.uakron.edu

Project Description

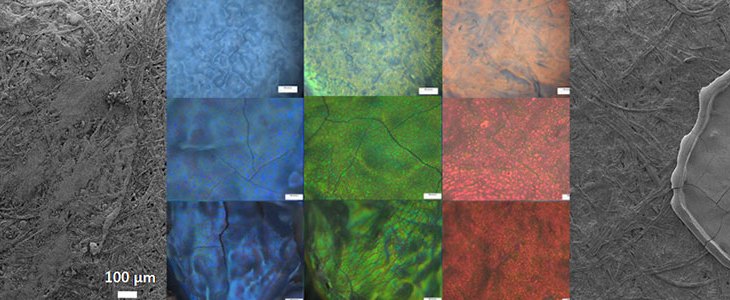

Structural color-based printing inks possesses several advantages to conventional pigmentary inks in terms of color perpetuity and cost effectiveness. However, there are certain challenges while using these structural color systems. Some of them include requirements for highly concentrated particle suspensions to avoid the coffee-ring effect during the printing processes, preparation of intricately patterned substrates to form hierarchical structures or to favor assembly of these particles to exhibit color, stabilization of such assemblies to prevent them from breaking apart due to external forces, and necessity to expand the color gamut showed by these systems. Thus, there is a need for an efficient technology to address the above challenges in an economical way.

When a simple suspension of ink particles (comprising of only solvent and solid particles) is added to a paper, it would be absorbed by the paper preventing any manifestation of color. To address the above concern, it is essential to perform a pre-treatment of the substrate surface to prevent absorption of these ink particles by the substrate and confine them to a small area where the droplets have been printed. By employing a cold plasma treatment (plasma-enhanced chemical vapor deposition), we obtain a superhydrophobic and an oleophobic surface having water contact angles higher than 130˚, allowing the confinement of particles in a small area when the solvent is evaporated.

Having the ability to print on paper, we want to expand on the idea and start printing on a vaierty of materials (e.g. metals, fabrics, plastics, ceramics, etc.). However, as we know, contact angle is material-dependant and this property significantly impacts the morphology and thus, the optical porperties of the printed dots. Having an understanding of what range of contact angles to be used for printing would enable one to overcome redundant surface pre-treatment processes (like cold plasma) to generate printed dots with desire optical properties.

Project Date

Spring, Summer and Fall 2020

Search Terms

Advanced Materials, Colloidal Science and Optics, STEM