How to Apply

Interested in participating in this research project? Contact the professor or graduate student listed below.

Professor

Dr. Siamak Farhad, Associate Professor; Interim Director of Center for Precision Manufacturing (CPM); (Department of Mechanical Engineering) | sfarhad@uakron.edu

Graduate Student

Joshua Campbell | jc414@uakron.edu

Project Description

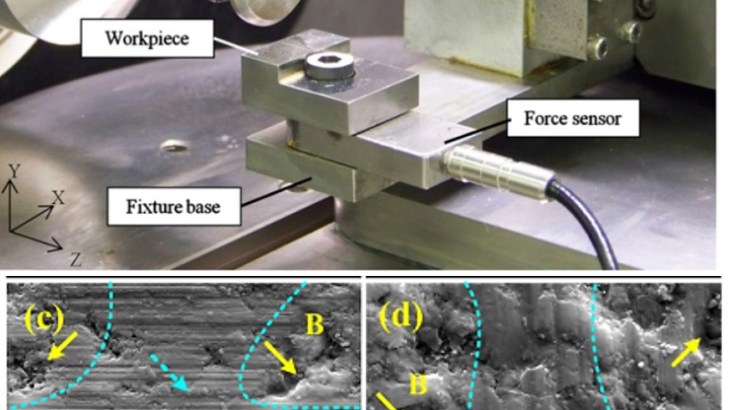

The grinding of brittle materials, such as ceramics, presents several unique challenges not found in the grinding of metals. Among these challenges are the use of diamond abrasives, the dressing of grinding wheels, a tendency towards higher specific energies, and the tendency of the workpiece to crack under grinding. In many applications, surface macro or micro cracking can result in a reject product. One application where ceramic material can be utilized is the rolling element in a bearing assembly. The ceramic material commonly used for this application is silicon nitride. Due to its high hardness and low fracture toughness, silicon nitride is difficult to grind without creating surface cracks. The removal modes of ceramic workpiece are either brittle or ductile. In the brittle mode, surface cracks are formed, and material is removed via surface fracture resulting in grain dislodgement. In the ductile mode, material is plowed in a ductile manner resulting in chip formation. The surface cracks are not formed in this mode. The objective of this project is to investigate these ductile/brittle mode removal mechanisms in relation to the grinding process. This project has an industry sponsor and it is related to Advanced Manufacturing, Advanced Materials, and Test System Design and Building. It is recommended to a Senior Mechanical Engineering student who decides to continue education at MSc/PhD levels at UA after graduation. The student can also make this project as his/her design project. In the first phase of the project the student will be paid based on 10 hours work per week. The following skills are required for this position: SolidWorks software (or can learn it fast) Problem solving Communications Internet search Hands-on works Self-learning

Project Dates

Summer 2021 – Spring 2022

Search Terms

Advanced Materials, Manufacturing, Funded